4th PEACE Project MeetingFirst Research Targets Met

Published: April 8, 2025

In early February 2025, the PEACE project coordinating institution, the DLR Institute of Engineering Thermodynamics, hosted the fourth all-hands project meeting in Stuttgart. This mid-term hybrid meeting assessed the progress of the PEACE’s research into highly pressurized alkaline electrolysis (AEL) where we aim to reduce the cost of (green) hydrogen production and its subsequent utilisation.

Fig. 1 PEACE Project meting No. 4, Source: GG (CC-BY-NC-ND 4.0)

By late 2024, the project had met its first major research targets: (1) the qualification of cell components, and (2) the design and production of stack components for high-pressure AEL operation. These achievements were discussed, and the next steps were outlined, as 2025 is set to be a year full of key milestones.

The meeting was opened by the Coordinator, Dr. Fatemeh Razmjooei, Institute of Engineering Thermodynamics at German Aerospace Center (DLR). She summarised the project’s main achievements at mid-term: PEACE has delivered twelve reports to the Clean Hydrogen Partnership (the granting authority) in accordance with the project plan.

The PEACE Project is going through mid-term reporting connected to a formal review process from the granting authority which is a great chance to step it up even more in the second half of the PEACE project implementation.

Fig. 2 PEACE Project team during the 4th project meeting, Source: DLR (CC-BY-NC-ND 4.0)

The Work Package (WP) Two (WP2) team at DLR summarised the latest findings on the qualification of cell components. The high-performance benchmark of 1 A/cm2 at 1.8V was fulfilled. Tested separators demonstrated comparable and reasonable gas purity within a specific current density range. Outcomes of this achieved task guided the careful selection of substrates and membranes, as well as informed the design of a PEACE cell. Cell design will be elaborated as to minimize contact resistances and reduce gas crossover which is assumed to be a major challenge for high pressure hydrogen production.

As outlined by TU/e’s contribution, the qualified components were undergoing further comparative testing at TU/e and DLR in a pressurized single cell under the following conditions: 50 barg, 80°C, and over 100 hours of continuous operation. Results are expected before summer 2025.

In WP3, MMI reached an important milestone at the end of 2024 with the design of the PEACE stack components. All the materials and technologies required for constructing the PEACE demonstrator stack were set with a vision of sustaining high-efficiency of the hydrogen production while lowering the overall cost of the stack.

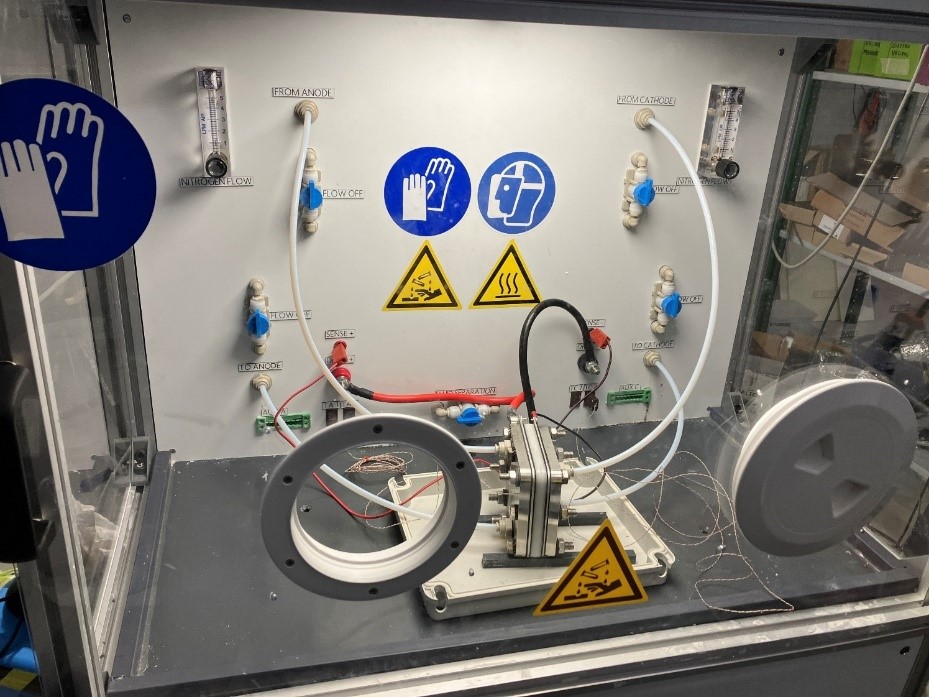

MMI designed and leak-tested under pressurized conditions a laboratory-scale cell for material evaluation. It was subsequently scaled up to a full-size model and measurements of performance for components such as elastic elements and O-ring gasketing were performed (see the test bench in Fig. 3). MMI is currently ready for the short stack assembly where the identified technologies and components will be integrated into a life-size object.

Fig. 3 MMI Test bench, Source: MMI (CC-BY-NC-ND 4.0)

BTU team is leading the WP4. In their presentation, they have concluded the Piping and Instrumentation diagram (P&ID) for the high-pressure setup of the PEACE demonstrator that would be mounted at their premises. They had already prepared the spot by dismantling the “old” test stack (see Fig. 4). Hardware and sensors for the demonstrator are on their way. Safety protocols and procedures are being developed in accordance with the Hazard and Operability (HAZOP) framework and the Failure Mode and Effects Analysis (FMEA) approach.

Fig. 4 The old BTU stack was cleaned and each cell was dismounted and stored, Source: BTU (CC BY-NC-ND 4.0)

The WP5 team at DLR presented its outcomes of the TEMPEST modelling framework to complete the PEACE electrolyser system (pressure vessel and other BoP parts). Operating strategies are currently defined to improve gas purity in the PEACE stack.

Simultaneously, DTU team works upon a life cycle assessment to quantify the environmental impacts of the PEACE technology. A set of life-cycle-inventory data for PEACE high pressure alkaline water electrolysis is currently under preparation with reference data collection.

WP6 leader, GG, sustains a continuous communication flow on the PEACE project towards the external audience through the PEACE website, PEACE X and LinkedIn profiles (Fig.5). Strong engagement and audience growth were reported supporting the project’s impact.

Fig. 5 PEACE Project Communication channels (website, LinkedIn, X), Source: GG (CC BY-NC-ND 4.0)

The meeting featured in-depth discussions, brainstorming, and knowledge sharing among all partners. We concluded that the PEACE project is progressing well, with significant research targets ahead. Stay tuned for further updates!

The project is supported by

the Clean Hydrogen Partnership and its members.

Co-funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or Clean Hydrogen Partnership. Neither the European Union nor the granting authority can be held responsible for them.